Learn all about the meaning of MEMS and their versatile applications. From definitions and how they work to practical applications, this guide offers you a deep insight into the world of microelectromechanics.

MEMS meaning: What are microelectromechanical systems?

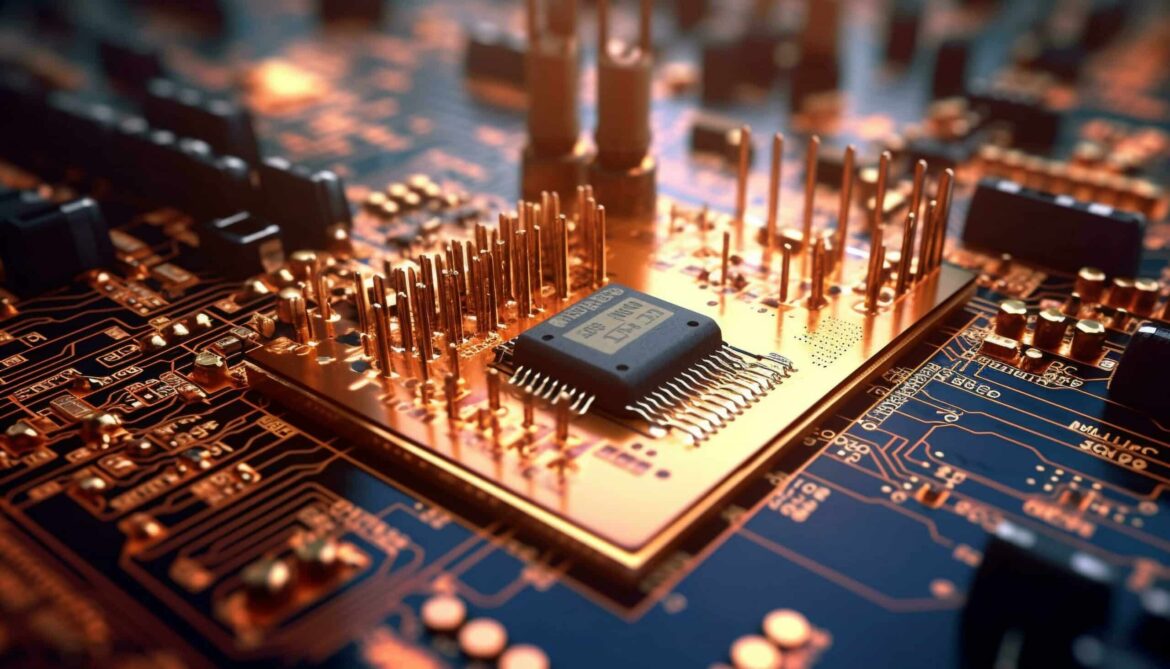

Microelectromechanical systems, or MEMS for short, play a crucial role in modern technology. But what exactly does this term mean? In this section, we will take a closer look at the basics and significance of MEMS.

- MEMS stands for microelectromechanical systems and encompasses tiny devices that combine electrical and mechanical components. These systems are often only a few millimeters in size, but consist of complex structures such as sensors, actuators, and electronic circuits.

- The development of MEMS began in the 1980s and has since revolutionized numerous industries, including the automotive, medical, and consumer electronics industries. Their ability to perform precise measurements in the smallest of spaces makes them an indispensable part of modern technology.

- A typical example of MEMS is an acceleration sensor, such as those used in smartphones or airbags. This sensor can detect movement and inclination and send corresponding signals to the device to trigger functions or activate safety mechanisms.

- MEMS are often manufactured using semiconductor manufacturing techniques such as photolithography. This enables the mass production of low-cost, high-precision devices that can be used in a wide range of applications.

MEMS applications and their advantages in everyday life

MEMS technologies are used in many areas and offer innovative solutions to everyday problems. Let’s examine some of the most notable applications and advantages of this technology.

- In the automotive industry, MEMS sensors are used to improve driving safety. For example, gyroscopes and acceleration sensors measure vehicle movements and help control stability systems such as ABS and ESP.

- In healthcare, MEMS devices enable advanced diagnostic methods and minimally invasive surgical procedures. Sensors monitor vital body functions, while actuators are used in micro-operations to perform high-precision movements.

- Consumer electronics also benefit from MEMS. In smartphones, they enable functions such as image stabilization in cameras or automatic screen rotation. Such sensors contribute to significantly improving the user experience.

- MEMS are also used in environmental monitoring. Sensors measure air quality, temperature, and humidity, providing valuable data for scientific research and combating environmental damage.

MEMS Functionality: How Microelectromechanical Systems Work

The functionality of MEMS is fascinating and highly complex. In this section, we delve deeper into the technical aspects of these systems and explain how they work.

- MEMS consist of microscopic components that work together through electromechanical processes. The main components include sensors, actuators, and integrated circuits that perform specific tasks.

- Sensors in MEMS systems detect physical quantities such as pressure, temperature, or motion and convert them into electrical signals. These signals are then processed by integrated circuits to trigger desired actions.

- Actuators in MEMS perform movements or other physical changes when controlled by electrical signals. Examples include tiny mirrors in projections or valves in microfluidic systems.

- The miniaturization of components is key to the functionality of MEMS. Modern manufacturing processes make it possible to integrate complex structures into the smallest of spaces, resulting in lightweight, robust, and energy-efficient devices.

Challenges and future prospects for MEMS technologies

Despite their numerous advantages, MEMS technologies face a number of challenges. Here we take a look at potential difficulties and future developments in this field.

- One of the biggest challenges in the development of MEMS is the complexity of manufacturing. Miniaturization requires precise manufacturing techniques that can be expensive and time-consuming. Improvements in these processes are necessary to make production more efficient.

- MEMS are sensitive to external influences such as vibrations or temperature fluctuations. This sensitivity can impair performance, which is why researchers are continuously working to increase the robustness and reliability of these systems.

- The integration of MEMS with other technological advances, such as the Internet of Things (IoT) and artificial intelligence (AI), opens up new possibilities. Through networking, MEMS data can be used to create smarter and more adaptable systems.

- The future of MEMS looks promising as new applications are constantly being discovered. In particular, there is great potential for innovations in medical technology and environmental monitoring that could further improve our daily lives.