184

If the stove cable is a few centimeters too short or you want to move the stove to a different location, you can simply extend the cable. In this home tip, we show you what you need to bear in mind when doing so.

Extending stove cables: A legal introduction

Extending a stove cable is not a trivial matter, but a safety-critical task. In this article, we summarize the most important points.

- In theory, a stove cable that is too short can be extended just like any other power cable. To do this, the respective wires of the two cables are connected to each other using luster terminals. Since high-voltage current sometimes flows through the cable, it must then be properly insulated. Insulating tape is not sufficient for this.

- However, in the case of a stove cable, the effort involved is not worth it and is far too dangerous, especially for laypeople. It is much cheaper to simply purchase a new stove cable.

- This is because, legally speaking, work on permanently installed stove connections may only be carried out by qualified electricians. Although DIY work is permitted, the actual connection and testing must be carried out by an electrician. Otherwise, insurance coverage and warranties or guarantees may be invalidated.

- It is also worth taking a look at the legal framework and VDE regulations. The connection of stoves is covered by the DIN VDE 0100 series. VDE 0100-520 regulates the selection of cables and wires in terms of load capacity and installation types. VDE 0100-430 requires protection against overload and short circuits (protection via circuit breakers), and VDE 0100-540 stipulates that a protective conductor connection is mandatory.

Cable types and co.: What you need to know about stove cables

If you would like more information about your stove cable, the following points will help you get an overview:

- In Germany, a three- or five-core NYM-J cable is usually used to connect an electric stove. The standard cross-section is 5 × 2.5 mm² (for three-phase current / 400 V). This type of cable is suitable because it offers high current carrying capacity and is heat-resistant, which is important for stove connections as heat radiation can occur. This type of cable also has secure insulation when laid close together in the wall or on the surface.

- These specific requirements must be observed. This is because a stove often draws between 7 and 11 kW of power. This means that high currents flow over a long period of time. Only cables with a sufficient cross-section and standard-compliant insulation prevent dangerous heating, voltage losses, and ultimately the risk of fire.

- The basic rule is: the longer the cable, the greater the voltage drop. According to the VDE standard, a maximum voltage drop of 3 percent is permissible up to the stove connection box. For a 2.5 mm² cable, the total length of the cable route should not exceed 20 to 25 m.

- Please also note that narrow cable ducts or exposure to heat increase the temperature even further. This should be taken into account during planning.

- To avoid overheating and voltage loss, no unnecessary transitions should be made.

Safety first: How to ensure it

When extending a stove cable, you should use safe, approved systems and seek the assistance of a professional.

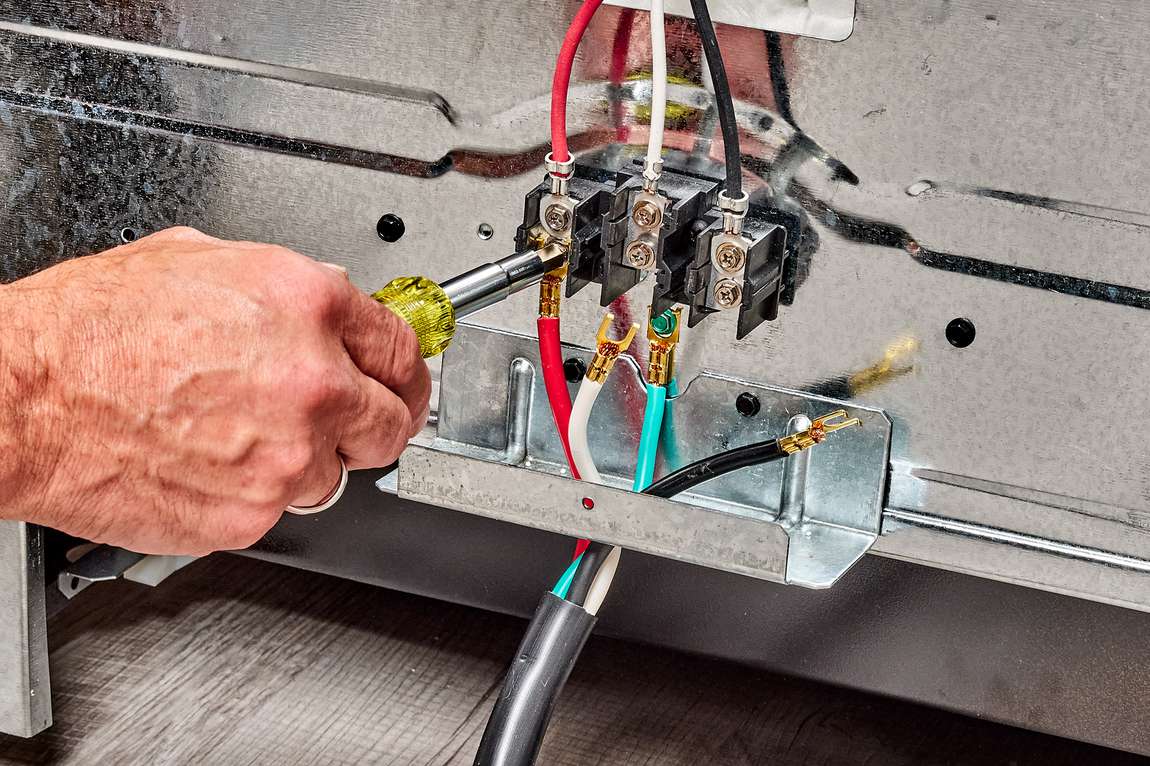

- One option is to use stove connection boxes. These provide secure terminals for all phases, neutral conductors, and protective conductors. You can also use special plug-in systems, such as Perilex or modern stove connection plug-in systems. These are easier to install and maintain.

- Avoid using luster terminals or improvised solutions! These quickly lead to loose connections and overheating.

- All connections must be located in closed, insulated enclosures and must not be freely accessible.

- If the cable is being newly laid or extended, you should hire a professional. Assistance is also recommended if it is unclear what cross-section and line protection are required.

- If a high-voltage connection (3-phase 400 V) is available or changes to the fuse box are necessary, a specialist company should also carry out the change. After completion, they will check the insulation values, loop impedance, and protective measures—a crucial step for your safety.